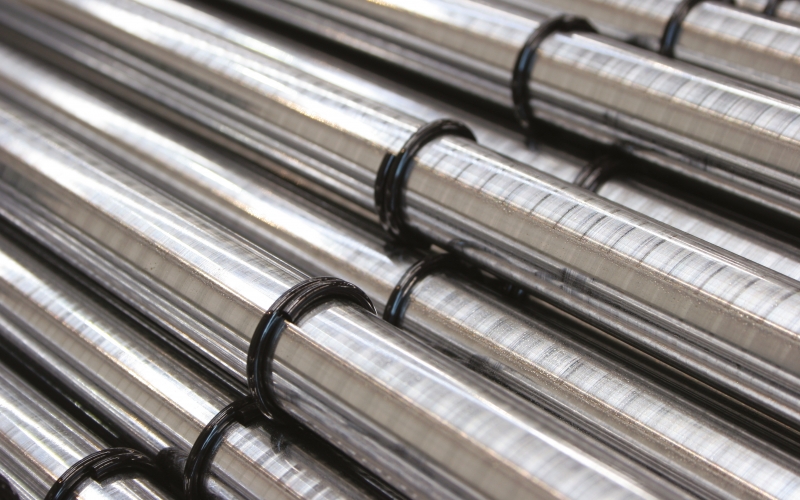

Ori Martin is able to satisfy the most stringent specifications concerning micro cleanness, surface decarburization and absence of surface defects.

Ori Martin special steels are used for the production of spiral springs with two process: cold forming of an induction pre-tempered wire and hot forming. Also torsion and stabilizer bars are common field of application of such steel grade.

Suitable for the production of coil springs and torsion bars used in the automobile and railway industries. These grades of steel must have a high yielding point and tenacity after quenching and tempering to withstand stress under flexi-torsion.

Our refining and casting techniques enable us to achieve steel with good hardenability and a high level of micro-cleanliness. Using the controlled rolling process we obtain products with a very low decarburisation level, absence of surface defects, tight tolerances and excellent characteristics of wire plasticity.

Steel grade

| Steel grade | Corresponding standard | Average chemical composition | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Werkstoff | ORI Martin | C | Mn | Si | Cr | Ni | V | ||

| Si | 38Si7 | 1.5023 | D38S71 | 0,38 | 0,70 | 1,70 | - | - | - |

| 48Si7 | 1.5021 | D50S72 | 0,48 | 0,65 | 1,80 | - | - | - | |

| 51Si7 | 1.5025 | D50S71 | 0,50 | 0,70 | 1,70 | - | - | - | |

| 55Si8 | D55S81 | 0,55 | 0,80 | 1,90 | - | - | - | ||

| Mn | 38Mn6 | B36M61 | 0,29 | 1,50 | 0,20 | - | - | - | |

| Si Cr | 54SiCr6 | 1.7102 | D55S51 | 0,54 | 0,80 | 1,40 | 0,70 | - | - |

| 56SiCr7 | 1.7106 | D55S71 | 0,55 | 0,70 | 1,70 | 0,20 | - | - | |

| 61SiCr7 | 1.7108 | D60F81 | 0,61 | 0,85 | 1,80 | 0,30 | - | - | |

| Si Cr V | 45SiCrV6-2 | 1.8151 | D45F61 | 0,45 | 0,80 | 1,50 | 0,60 | - | 0,15 |

| 54SiCrV6 | D56F71 | 0,54 | 0,70 | 1,40 | 0,70 | - | 0,10 | ||

| 61CrSiV5 | 1.2243 | D61F72 | 0,61 | 0,75 | 0,85 | 1,15 | - | 0,10 | |

| 65CrSiV7 | D65F81 | 0,65 | 0,85 | 1,50 | 0,80 | - | 0,23 | ||

| Mn Si Cr V | 45MnSiCrV6 | D45F66 | 0,45 | 1,30 | 1,40 | 0,60 | - | 0,15 | |

| Cr | 55Cr3 | 1.7176 | D55C31 | 0,55 | 0,80 | 0,30 | 0,80 | - | - |

| Cr V | 50CrV4 | 1.8159 | D50X41 | 0,50 | 0,80 | 0,30 | 1,00 | - | 0,15 |

| 58CrV4 | 1.8161 | D58X41 | 0,58 | 0,90 | 0,30 | 1,00 | - | 0,15 | |

| Si Cr Ni | 52SiCrNi5 | 1.7117 | D52R51 | 0,52 | 0,85 | 1,35 | 0,85 | 0,60 | - |

Products

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

A new IT wire line has been installed in Brescia’s plant, the final part of a fully integrated process from continuous casting of billet to rolling of wire rod. Coils are handled with the utmost care, so as to preserve and protect their surface.

ORI Martin Group is proud to offer a 100% controlled product, from raw materials to pre-tempered wire. 25 years of experience in the production of steel for suspension springs in the automotive sector have been one of the main reasons leading ORI Martin Group to invest in this new product. IT wire responds to the needs of cold coiled springs for high tensile strength and fatigue resistance. Pre-tempered wire can also be used in other different critical manufacturing fields.

Sales: ORI Martin S.p.A.

Sales: ORI Martin France Sarl

Sales: ORI Martin Deutschland GmbH

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Sales: Trafilati Martin Srl

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278