Surface hardening and case hardening steels

The homogeneity of the chemical composition together with an adequate micro cleanness, enable ORI Martin special steels to guarantee constant results in the final processes of our customers.

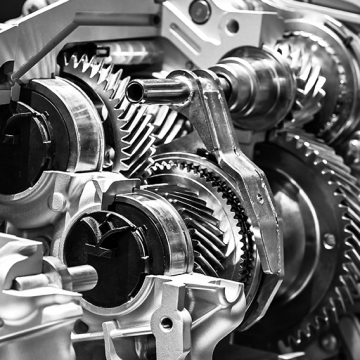

The surface hardening treatment achieves the wear resistance requested by hubs, shafts, gears and similar products.

Steel grade

| Steel grade | Corresponding standard | Average chemical composition | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Werkstoff | ORI Martin | C | Mn | Cr | Ni | Mo | S | V | ||

| C | C10E | 1.1121 | CC10X1 | 0,10 | 0,50 | - | - | - | - | - |

| C15E | 1.1141 | CC15L1 | 0,15 | 0,50 | - | - | - | - | - | |

| Mn Cr | 16MnCr5 | 1.7131 | C16U51 | 0,16 | 1,20 | 1,00 | - | - | - | - |

| 16MnCrS5 | 1.7139 | C16U52 | 0,16 | 1,20 | 1,00 | - | - | 0,03 | - | |

| 20MnCr5 | 1.7147 | C20U51 | 0,20 | 1,25 | 1,10 | - | - | - | - | |

| 20MnCrS5 | 1.7149 | C20U52 | 0,20 | 1,25 | 1,10 | - | - | 0,03 | - | |

| 27MnCr5 | / | C27U51 | 0,27 | 1,25 | 1,20 | - | - | - | - | |

| 12CRMo4 | 1.7201 | S12L41 | 0,12 | 0,75 | 1,05 | - | 0,20 | - | - | |

| Cr Mo | 18CrMo4 | 1.7243 | C18L41 | 0,18 | 0,70 | 1,00 | - | 0,20 | - | - |

| 15-20CrMo5 | 1.7264 | 0,20 | 1,05 | 1,25 | - | 0,25 | - | - | ||

| 13CrMo4-5 | 1.7335 | 0,13 | 0,70 | 0,93 | - | 0,50 | - | - | ||

| 25MoCr4 | 1.7325 | 0,26 | 0,75 | 0,50 | - | 0,45 | - | - | ||

| 25CrMo4 | 1.7218 | C25L41L | 0,25 | 0,75 | 1,05 | - | 0,22 | - | - | |

| Ni Cr | 19CrNi5 | / | C19R51L | 0,20 | 0,90 | 1,00 | 1,00 | - | - | - |

| 10NiCr6 | / | C10R61L | 0,10 | 0,70 | 1,05 | 1,28 | - | - | - | |

| 12NiCr3 | / | C12R31 | 0,12 | 0,60 | 0,60 | 0,70 | - | - | - | |

| 16NiCr11 | / | C16R11 | 0,15 | 0,45 | 0,75 | 2,75 | - | - | - | |

| 16CrNi4 | 1.5714 | C16R41 | 0,16 | 0,60 | 1,00 | 1,00 | - | - | - | |

| 17CrNi6 | 1.5918 | C16R61 | 0,16 | 0,60 | 1,50 | 1,50 | - | - | - | |

| 15NiCr13 | 1.5752 | 0,17 | 0,55 | 0,75 | 3,25 | - | - | - | ||

| 14NiCr14 | / | 0,17 | 0,55 | 0,75 | 3,50 | - | - | - | ||

| 18MnNiCr4 | / | C17H22 | 0,18 | 1,23 | 0,45 | 0,45 | 0,06 | - | - | |

| Ni Cr Mo | 20NiCrMo2 | 1.6523 | C20H21 | 0,20 | 0,70 | 0,50 | 0,60 | 0,20 | - | - |

| 17NiCrMo6-4 | 1.6566 | C18H51 | 0,18 | 0,70 | 1,00 | 1,30 | 0,20 | - | - | |

| 20MnNiCrMo3-3 | 1.6527 | C20H23 | 0,20 | 0,85 | 0,50 | 0,80 | 0,20 | - | - | |

| 13CrNiMo7-6 | / | C13H71 | 0,14 | 0,50 | 1,40 | 1,60 | 0,25 | - | - | |

| 18CrNiMo7-6 | 1.6587 | C18H71 | 0,18 | 0,70 | 1,65 | 1,55 | 0,30 | - | - | |

| 20NiCrMoS2-2 | 1.6526 | C19H21 | 0,20 | 0,80 | 0,52 | 0,55 | - | - | - | |

| Cr Mo V | 31CrMoV9 | 1.8519 | B31K92 | 0,31 | 0,55 | 2,50 | - | 0,20 | - | 0,15 |

| Mn Ni Cr Mo | 23MnNiMoCr5-4 | 1.6758 | C23H54 | 0,23 | 1,30 | 0,50 | 1,00 | 0,50 | - | - |

| 23MnNiCrMo5-2 | 1.6541 | C23H53 | 0,23 | 1,25 | 0,50 | 0,55 | 0,25 | - | - | |

| 15Mo3 | 1.5415 | C15D31 | 0,16 | 0,65 | - | - | 0,30 | - | - | |

| 20MnCrNi4-2 + B | / | S20HB1 | 0,22 | 1,10 | 0,60 | 0,50 | 0,10 | - | - | |

| SAE 4720 | / | C20H22 | 0,20 | 0,60 | 0,45 | 1,05 | 0,20 | - | - | |

| 27MnSi5 | 1.0412 | C27E51 | 0,27 | 1,50 | - | - | - | - | - | |

Products

Wire rod

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Rolling takes place at a controlled temperature using the very latest technology. This allows a smaller grain size to be obtained together with a more fine and even structure. Optimal characteristics for subsequent use in drawing and cold moulding in addition to a higher degree of globularisation after the annealing process.

Hot rolled bars

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Production takes place in a rolling mill at a controlled temperature using the very latest technology which guarantees a fine grain and homogeneous structure; the calibrator finishing block allows bars with restricted dimensional tolerances.

Continuous casting billets

ORI Martin spa sells continuous casting steel billets to rolling mills and hot forgers. The refining process with the degassing station and the casting through submerged nozzles guarantee the supply of billets of high-quality engineering steel.

ORI Martin spa sells continuous casting steel billets to rolling mills and hot forgers. The refining process with the degassing station and the casting through submerged nozzles guarantee the supply of billets of high-quality engineering steel.

Sales: ORI Martin S.p.A.

Sales: ORI Martin France Sarl

Sales: ORI Martin Deutschland GmbH

Cold drawn bars

Cold drawn bars are cold finished products achieved by the cold deformation of the wire rod through a die that reduces the diameter and after various controls are cut into the length required. This process achieves the calibration of the wire into the diameter required. We can obtain wire in a wide range of diameters, the mechanical characteristics increase depending on the reduction carried out.

Cold drawn bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after drawing)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Cold drawn bars are cold finished products achieved by the cold deformation of the wire rod through a die that reduces the diameter and after various controls are cut into the length required. This process achieves the calibration of the wire into the diameter required. We can obtain wire in a wide range of diameters, the mechanical characteristics increase depending on the reduction carried out.

Cold drawn bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after drawing)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

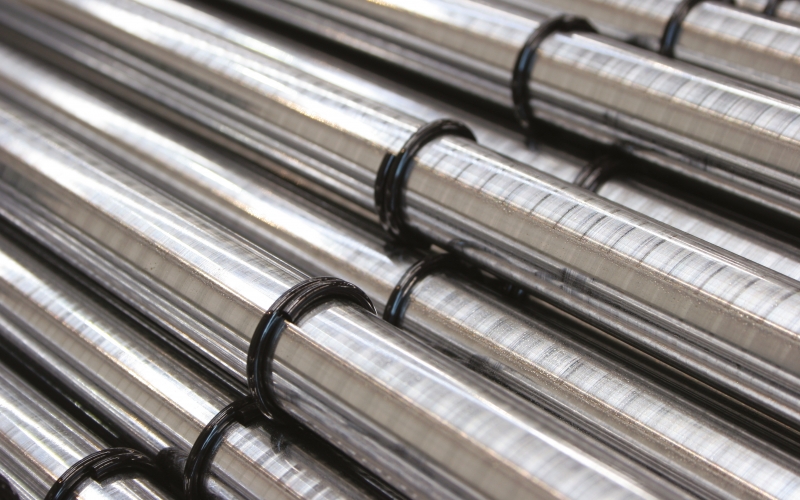

Peeled bars

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Peeled bars from 17 to 80 mm.

Peeled bars from hot rolled bars can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

- Ultrasonic test

Peeled bars from hot rolled coil can be produced with the following additional operations and controls:

- Heat treatment by annealing (soft and spheroidized annealing and so on)

- Heat treatment by quenching and tempering, normalising or stress reliving by induction (after peeling)

- Ends chamfering

- Surface defect control by Eddy Current

- Anti-mixing control

Sales: Trafilati Martin Srl

Peeled & reeled bars

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Peeled & reeled bars (+SH EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 10,00 ÷ 200,00 ( ≥IT9 ) EN 10278

Cold drawn bars

Cold drawn bars (+C EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 8,00 ÷ 74,00 ( ≥IT9 ) EN 10278

Cold drawn bars (+C EN 10277)

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 8,00 ÷ 74,00 ( ≥IT9 ) EN 10278

Ground Bars

Ground bars

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278

Ground bars

Alloy Steel, Non-Alloy Steel and Stainless Steel

Ø 6,00 ÷ 200,00 (IT9 ÷ IT6) EN 10278